Why buy our 3D Printing Resin Bottle Mixer with Active Heating

This is a bi-directional mixer – it doesn’t just a roll a bottle like most consumer mixers on the market – it actually wobbles the bottle to shake it without bubbling the resin.

Did you know that many common 3d print failures are related to the resin not being mixed properly or being too cold?

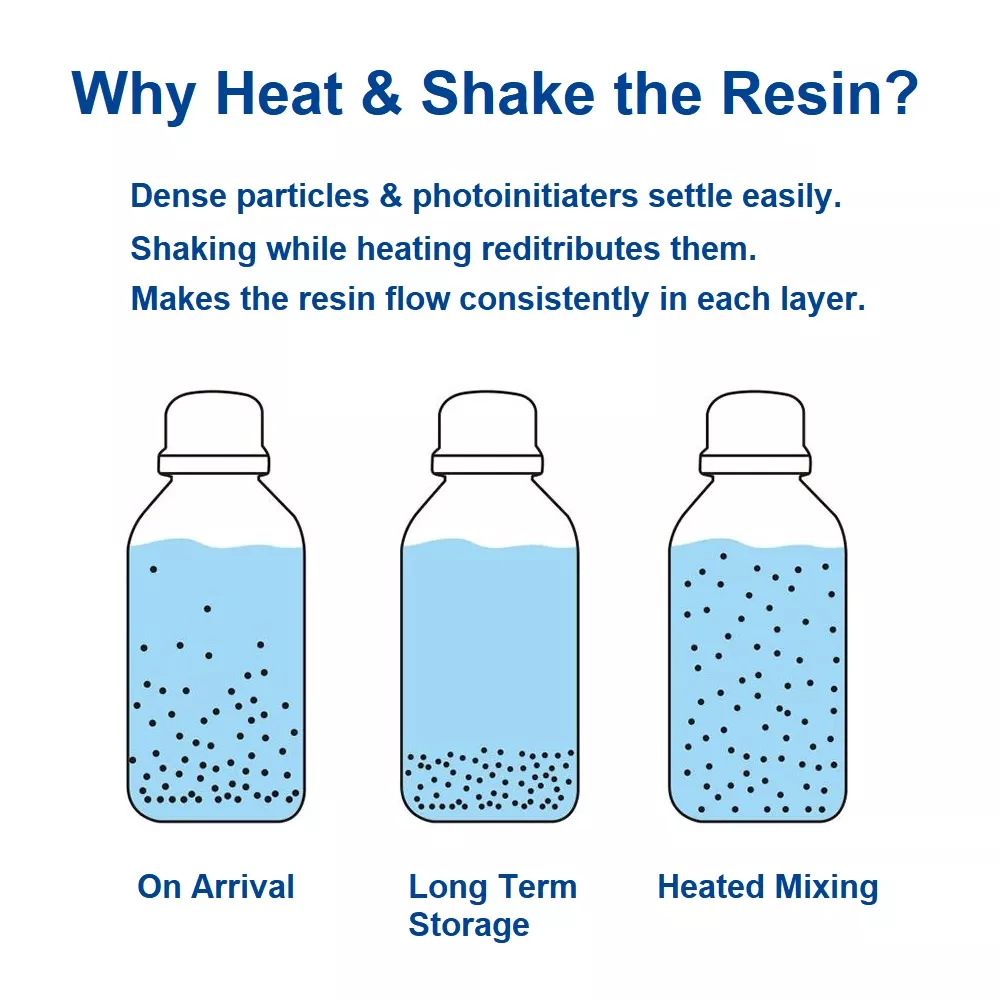

Since most bottles are stored standing upright, it is very common for resin monomers & pigments to settle downward.

So when you then use the resin, it has actually separated. This is why the resin needs to be thoroughly mixed.

Simply shaking the resin bottle is not the best option, because shaking it induces bubbles & causes uneven coagulation of the chemicals.

This bottle roller rotates resin bottles inside a heated chamber to mix the resin thoroughly.

By heating the resin while it is being mixed, the nanoparticles that have settled are able to retake a uniform viscosity.

Resins that are heated are less viscous & print much better than when the resin would be thicker.

This mixer provides a consistent & easy solution to shaking the bottle by hand, as just shaking the bottle heavily can cause the resin to bubble rather than actually mixing correctly.

With our heated resin bottle roller, you will greatly reduce print failures caused by the resin being too cold, particularly in winter.

This mixer is particularly useful if you plan to 3d print high performance industrial engineering resins, wax castable resins, ceramic filled or dental resins.