Choosing Between FDM and Resin 3D Printers: A Quick Guide

Are you exploring 3D printing options but unsure whether to choose an FDM or a resin printer? Each type has unique strengths and applications, and understanding the differences can help you select the right one for your needs. Here’s a guide to help you choose between FDM (Fused Deposition Modeling) and resin 3D printers, with an updated look at resin printing’s latest advancements.

Understanding FDM and Resin Printing Technologies

FDM (Fused Deposition Modeling) 3D Printers:

FDM is also called FFF (Fused Filament Fabrication).

These 3d printers are the most widely used and work by pushing out (extruding) melted plastic filament layer by layer to build a 3D object.

This method is straightforward, highly accessible, & you can often just pick up & start using the part as soon as its 3d printer.

This technology offers a range of materials, from basic PLA to more specialized filaments like ABS, PETG, and TPU.

Resin (SLA/DLP) 3D Printers:

Resin printing is based on a broad technology called StereoLithography.

Resin printers use a liquid polymer (called a photopolmer) that hardens under UV light to create highly detailed layers of solid plastic.

This process is perfect for applications requiring fine detail, such as miniatures, jewelry, and dental models.

The part is wet when completed, & has to be post processed before it can be used.

The latest resin printers now support water-washable resins and come with convenient washing and curing units, making them more user-friendly and efficient than ever.

Comparing FDM and Resin Printers

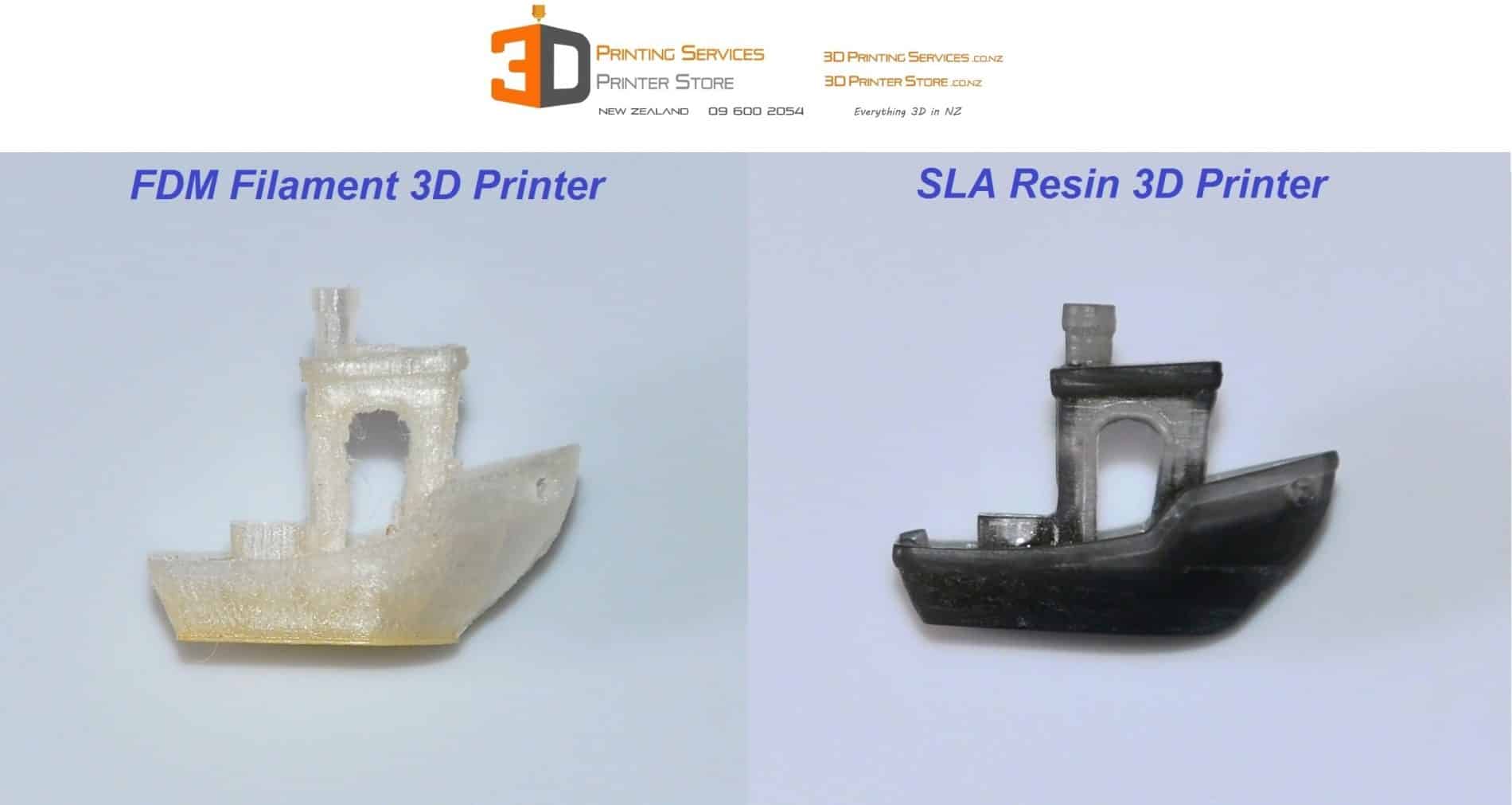

1. Print Quality and Detail

FDM Printers: FDM is excellent for larger prints and structural parts where extreme detail isn’t necessary. Layer lines can be visible, though newer FDM printers and settings can minimize them.

Resin Printers: Resin printers excel in detail, creating smooth surfaces and high-resolution prints. With water-washable resins, cleaning is now simpler and safer, and wash and cure units streamline the entire post-processing experience.

2. Material Variety

FDM Printers: FDM offers diverse, accessible materials. Common options include PLA, ABS, PETG, and even specialty filaments like wood-filled or carbon fiber.

Resin Printers: Resin types continue to expand, including flexible, tough, and castable resins. The introduction of water-washable resins has made resin handling easier, reducing the need for isopropyl alcohol and allowing quicker cleanup.

3. Ease of Use and Maintenance

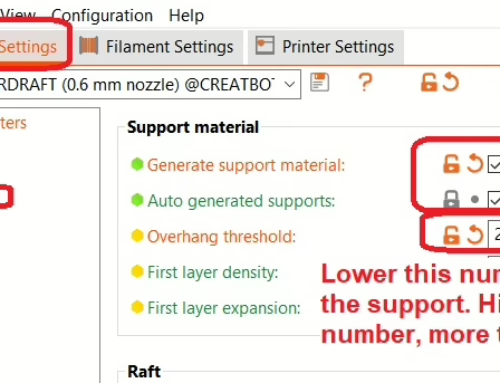

FDM Printers: FDM printers are generally straightforward to set up and maintain, requiring minimal post-processing.

Resin Printers: Resin printers were traditionally more complex, but with wash and cure stations, water-washable resins, and simplified post-processing, they’re now easier to work with. These units automate the cleaning and curing processes, which saves time and effort.

4. Printing Speed

FDM Printers: FDM speeds vary with layer height and complexity, generally faster for larger, less detailed parts.

Resin Printers: Resin printers cure entire layers at once, often faster for high-detail prints. Wash and cure units also speed up the post-processing, making resin printing quicker and more efficient.

5. Cost and Budget

FDM Printers: FDM printers are budget-friendly, and filament is generally inexpensive, making them ideal for prototyping and larger projects.

Resin Printers: Resin printers can have higher upfront and ongoing costs, especially with specialized resins and wash and cure units, but water-washable resins reduce the need for extra cleaning supplies, making them more economical.

6. Environmental Considerations

FDM Printers: FDM filament, especially biodegradable options like PLA, is typically more eco-friendly.

Resin Printers: Water-washable resins make it easier to handle and dispose of waste, reducing environmental impact compared to traditional resins.

Choosing the Right Printer for Your Needs

Go for a FDM 3D Printer if You:

Want an affordable, versatile option with many material choices

Need to 3D Print with Carbon Fiber reinforced filaments or composite materials

Plan to print larger, structural functional parts, without organic detail requirements

Value the accessibility of filament options

Prefer a simpler setup with minimal post-processing

Opt for a Resin 3D Printer if You:

Need high-detail, smooth-surface finishes for intricate or small objects

Appreciate simplified post-processing with water-washable resins and wash and cure units

Require precision for specialized applications like models, miniatures, or dental work

Are ready to invest in higher quality and detail

Top Picks

Choosing between FDM and resin printers depends on your specific goals.

FDM is versatile, affordable, and ideal for everyday projects.

Resin printers, with advancements like water-washable resins and wash and cure units, are now easier to work with and offer unmatched detail for intricate prints.

By understanding these differences, you can make the best choice for your 3D printing journey.

In many cases, you have a massive advantage buying one of each.

For FDM, we highly recommend the Creatbot F430 3D Printer which is our #1 selling 3d printer.

For Resin, we can’t sing enough praises for the Phrozen Mega 8K.

Wanna buy both? Try our Ultimate Desktop 3D Solution & you’ll never look back..

Need more guidance?

We’re here to help you find the right 3D printer for your needs. Please reach out to us.