-

This is the small PCB that goes behind the extruders of a Creatbot F430 head. The main ribbon cable connects to it from the motherboard underneath the machine. And other connectors such as the temp sensors, cartridge heaters, probe etc plug into this little board.

-

Restore broken parts to their original shape. Fill gaps and holes in models. Easy to sand and paint on after curing. Applicable on cured resin and plastic.

-

This is the USB reader board used on a Creatbot F430 & F160 3d printer. This is the Latest version board with an adapter to allow certain older printer models to also be able to use it.

-

This is a temperature sensor for the newer FlashForge Creator Pro 2 & Creator 3 Pro 3d printers. It is a threaded type that fits into the hot end block. This is not for older flashforge Creator series printers.

-

This motor is used in the Creatbot F430 3d printer. It is the X axi motor that connects on the linear rail to move the head left to right. This is the motor only, not the fan/heatsink. Please remember to put the heatsink & fan from your old motor onto the new motor.

-

Full Swappable Extruder Head for the new FlashForge Creator 4 3D Printer. 3 Extruder options available: HS Extruder = High Temp 360C Extruder including Carbon Fiber filled materials. HT Extruder = upto 320C temp for common plastics including PLA/ABS. F Extruder = Specialist flexible filament extruder for high flex TPU TPE & similar materials. Please specify which head you want on the order notes.

-

Genuine FlashForge nozzle for the FlashForge Guider 2S 3D Printer. It is common for nozzles to wear or block after a period of use, & need replacing. Simply unscrew the existing nozzle & screw the new one on, easy. Please remember to always heat your hot end before removing your nozzle.

-

Head board for 3d printers like Wanhao i3 plus mk2, D6, D9, D9 mk2 etc. This is the little PCB that sits on top of the main head where you plug in the heater, temp sensors, etc.

-

Genuine Wanhao Branded lower metal sheet to be stuck on the printer platform, on which you can then use magnetic mats & magnetic sensors. This is used on Wanhao i3 Mk2 (also called i3 v2) 3d printers, the new version of D5s, & other such machines. This is not the actual print surface, its the metal sheet on which the build surface sticks magnetically. For older version of the i3 please buy the other BuildTak style bed mat which has glue on one side. Works extremely well for most materials like PLA, ABS & PETG.

-

Extruder Circuit Board for FlashForge Adventurer 3 3D Printers

-

Magigoo HT adhesive is designed to provide bed adhesion with challenging materials like PEI Ultem, PEEK, PEKK, PPS, PSU, PPSU etc. It can be used with all kinds of bed surfaces, however we recommend PEI or Garolite. It can also be used with Carbon Fiber reinforced filaments & Glass Filled materials, like PPS-CF, PEI-CF & PEEK-CF etc. To 3D Print Nylon, we recommend Magigoo PA as a first choice, & if that doesn't suit well for your particular filament, then try this Magigoo HT. For common materials like PLA, ABS etc, we recommend buying the Magigoo original glue. Magigoo glue reduces warping in FDM 3D printers. Warping is caused by the differential cooling of a print during a 3D printing process made up of layers. For printing advanced materials reliably, apply a thin layer of Magigoo on your print bed before printing. This will ensure a successful print. If too much glue has been lacquered on, please wipe with a damp sponge & then reapply glue.

-

Magigoo Original adhesive is designed to provide optimum bed adhesion with PLA, ABS, ASA, PETG & other common materials. It can be used with all kinds of bed surfaces, however we recommend PEI or Garolite. It can also be used with Carbon Fiber reinforced filaments & Glass Filled materials. To 3D Print Nylon, we recommend Magigoo PA. For higher temp filaments including PEI & PEEK, we also have Magigoo HT. Magigoo glue reduces warping in FDM 3D printers. Warping is caused by the differential cooling of a print during a 3D printing process made up of layers. For printing advanced materials reliably, apply a thin layer of Magigoo on your print bed before printing. This will ensure a successful print. If too much glue has been lacquered on, please wipe with a damp sponge & then reapply glue.

-

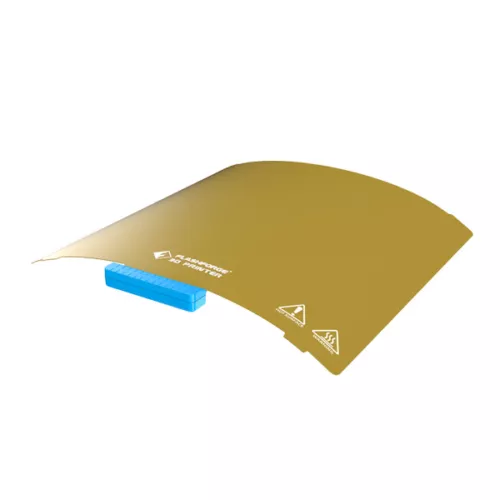

This is the latest flexible build plate that fits on the new magnetic beds of FlashForge Creator 4 3D Printers. It now has a PEI reinforced build surface that provides excellent adhesion to most common materials including flexible TPU materials. It also gives a very good bottom surface finish. It is superior to the older Black plates that FlashForge used to supply. We highly recommend PEI sheets as the best surface to print on. For Nylon based materials, we still recommend you put a thin layer of the glue stick on it.

-

Why use Ultrasonic cleaners when Wash & Cure units seem to be so easy to use? Short answer, high speed & less manual work. Ultrasonic vibrations loosen out debris from any surface surface efficiently & quickly using harmless forces. The frequency of motion they form safely dislodges uncured resin particles at a microscopic level that other devices cant create. Ultrasonic cleaners can clean most resin parts in 3 mins. Most entry level washers can't beat that. The fact that there is no heavy movement, allows debris to settle rather than float around. This makes it far easier to get the parts clean with less fluid use. When cleaning castable resins or industrial resins in particular, ultrasonic cleaners will give you the edge.

-

Genuine Creatbot door handles. These are the slim thin silver coloured aluminum door handles on newer Creatbot 3d printers with hinged doors. They are the smaller size (approx 80mm long), which are used for DX, DE, F160. They are also used on the rear chamber doors of the F430. These are attached to the Acrylic doors on the D series, & corresponding door frames on F series machines.

-

Why use Ultrasonic cleaners when Wash & Cure units seem to be so popular? Ultrasonic vibrations loosen out debris from any surface surface efficiently & quickly using harmless forces. The frequency of motion they form safely dislodges uncured resin particles at a microscopic level that other devices cant create. Ultrasonic cleaners can clean most resin parts in 3 mins. Most entry level washers can't beat that. The fact that there is no heavy movement, allows debris to settle rather than float around. This makes it far easier to get the parts clean with less fluid use. Resin cleaning liquids like Monocure Resin away & Phrozen now make it a cheaper & safer option than to use IPA or other explosive alcohol based cleaners. When cleaning castable resins or industrial resins in particular, ultrasonic cleaners will give you the edge.