The CreatBot PEEK-300 is an ultra performance 3D printer specially optimised to work with ultra high performance advanced materials such as PEEK, PEKK, PEI (Ultem tm), etc polymers in a dedicated no-compromise environment. It is designed for high reliability and industrail performance at a price that is substantially cheaper than industrial additive manufacturing systems.

Ultra performance Polymers & Composites are the future in additive manufacturing of production parts on demand.

Special Features found only on the Creatbot PEEK 300:

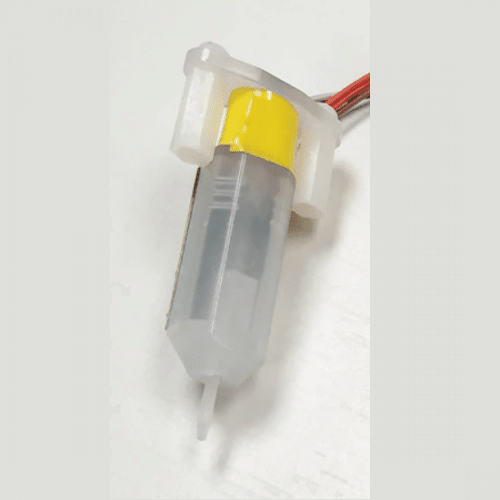

- Water cooled triple heat isolation heads

- Patented 400C Direct Annealing Air system.

- 480 C Dual Lifting Extruder Heads

- 120 C Active Heated Chamber

- 200 C Heated Bed

Build volume 300 x 300mm x 400mm height

From the company that brought you the first affordable desktop grade PEEK capable 3D Printer, now comes a work horse that is designed to deliver cutting edge factory parts in a semi-production capacity.

3d Print on demand in Automotive, Aerospace, Medical, & R&D specifically using PEEK & its related family of plastic filaments.