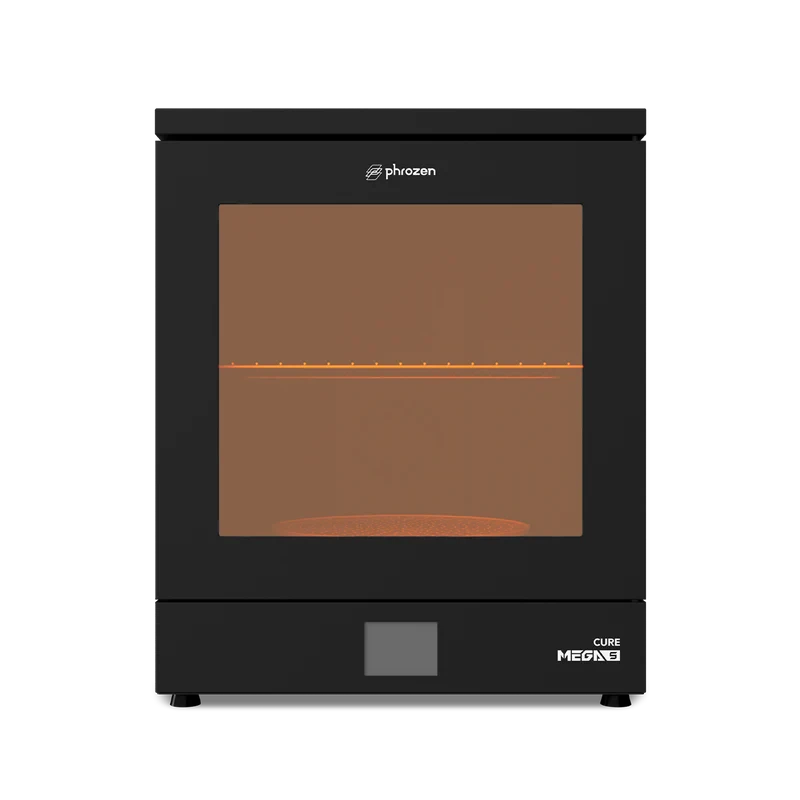

Phrozen Cure MEGA S – UV 3D Print Cure Lamp

Large 3d prints need proper curing.

This Phrozen Mega Curer comes with 40 X 40 X 35cm mega chamber size designed to complement 15″ LCD 3d printers like the Phrozen Mega 8K.

With 405nm UV lights and a 360-degree rotating stand, Phrozen Cure Mega cures large prints or multiple smaller-sized models reliably, regardless of size.

Without proper curing, prints can easily fail. Don’t let your models fail at this crucial stage.

Cure your models in the chamber and with a click of a button, your models will be properly cured.

This is a Back Order special. Buy now, Save a Lot.

Includes a timer system for compatibility with all your resins.

Works fine with 3d prints made by all popular resin 3d printers on the market.

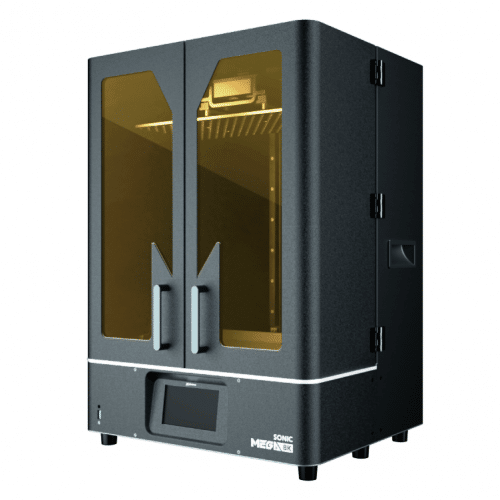

And the Perfect match for our large Phrozen Mega 8K Resin 3d printer

There are myths around curing with sunlight. Though sunlight has UV in it, there is very less intensity of 405nm wavelenth UV that is needed to cure 3d prints.

Enough UV to give you a sun burn, sure. But to cure a 3d print – not really.

The correct UV wavelength is able to penetrate part surface, sunlight can not.

Sunlight will also heat up your model much more than the UV you would get to polymerise the liquid.

Curing in the sun heats up models unevenly, & causes distortion.

A curer rotates as it exposes UV, thereby raising the part temperature evenly.

This improves the interlayer adhesion & creates strong components that exhibit the qualities the resin makers expected you to achieve.

A poorly cured part is not a safe practise – you don’t want these monomers floating everywhere long term.

Curing 3d printed parts correctly, is important so that things are not contaminated. And people are safe to touch them.