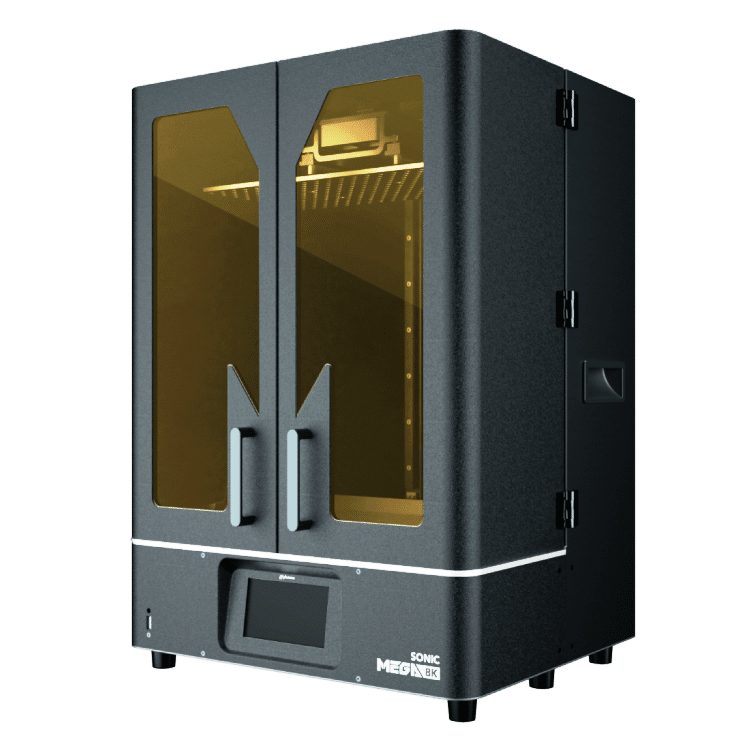

Phrozen Sonic MEGA 8K V2 15″ Mono LCD 3D Printer

The largest 8K mono LCD Resin 3D Printer in the world has been upgraded.

The Mega 8K V2 has a faster print speed, automatic resin filler, & a drip hook.

With a massive build volume of 330mm x 185mm x 400mm & 43 micron XY resolution, you can build large parts without compromising detail or running out of resin.

This is a game changer.

We’re proud to have the newest 8K Monochrome 15″ LCD resin 3d printer available in New Zealand.

Please note we are the Exclusive Official Reseller of Phrozen in New Zealand.

We provide local support & a legitimate warranty. Buy from us & get access to genuine spare parts locally.

Buying from random shops means no manufacturer warranty, no support or repairing as they will not have parts on hand.

They have most likely just parallel-imported the machines, & should something go wrong, you might find yourself stuck.

These machines are highly sought after, & have sometimes 1-2 months production delay.

Traditionally, larger resin machines had lower resolution, but with the Mega 8K screen, you get a 43um XY unlike anything else on the market at this price.

When a Big 3d Printer isn’t enough, you need a Phrozen MEGA!

Liquid Resin 3d printers used to be small & expensive. So they were used only by jewellers & dentists.

Today, thanks to Phrozen, we now have a massive printer area in liquid resin technology giving everyone access to factory quality layerless parts at a price point that is unheard of.

The Mega 8k revolutionises 3d printing & enables you to make parts that can be sold directly to customers – without them looking 3d printed.

Happy Resin 3D Printing!