Which is the Best High Speed 3D Printer in NZ?

When shopping for a high-speed 3D printer, you’ll often come across popular models like the Bambu Lab P series and Creality K series, which promise blazing-fast FDM printing speeds.

But the big question: How fast are they at actually getting the part done, & more importantly, do they really maintain high speeds with all types of materials, especially advanced ones like carbon fiber, nylon, and engineering-grade polymers?

The Limitations of Fast FDM Printing

High-speed FDM (Fused Deposition Modeling) printing works well for common materials like PLA and PETG, but when it comes to more demanding filaments, things change drastically. While some high-speed FDM printers can handle advanced materials, most affordable high-speed options struggle for several reasons:

- Carbon Fiber and Nylon Require Specialized Hotends: Many high-speed FDM printers, including models like the Bambu Lab P1 series and Creality K1, don’t come equipped with the necessary hardened steel nozzles or high-temperature hotends needed for carbon fiber-infused or nylon materials. These materials often require an all-metal hotend rated above 300°C and a heated chamber for optimal results. Users often need to upgrade components to print these materials reliably.

- Warping and Layer Adhesion Issues: Printing advanced materials at high speeds can cause warping, delamination, and poor interlayer bonding, forcing users to slow down print speeds—negating the benefits of a high-speed machine.

- Enclosure and Heat Management Matters: Many high-speed FDM printers lack fully enclosed, actively heated chambers. This is crucial for consistent results with ABS, ASA, PC, and other engineering-grade filaments.

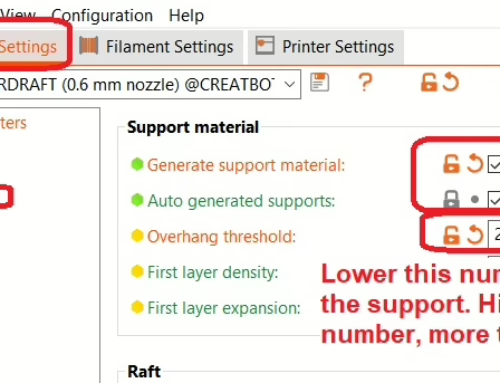

- Fast Travel Movements Reduce Part Strength: Printing at very high travel and extrusion speeds often leads to weaker part strength. A so-called “standard” printer using a slightly larger nozzle (e.g., 0.6mm or 0.8mm instead of the common 0.4mm) can dramatically increase output while significantly improving inter-layer and inter-wall adhesion. In FDM printing, thicker and larger extrusion segments result in stronger parts due to better fusion between layers. Conversely, thin, fast layers do not automatically translate to stronger or better-quality prints.

The Real High-Speed Printing Solution: Resin 3D Printing

While many people assume high-speed FDM is the answer, resin printing actually achieves much faster print times with fewer compromises. Unlike FDM, which prints line-by-line, resin printers cure entire layers at once, dramatically reducing print time. Here’s why resin 3D printing is often the better choice:

- Consistent Speed Across All Materials: Resin printers don’t need to slow down for advanced resins. Whether you’re printing a simple model or a high-temperature engineering part, the print speed remains the same.

- No Warping or Layer Adhesion Issues: Resin parts are built with uniform exposure, reducing internal stress and eliminating common FDM issues like warping and delamination.

- Factory-Quality Surface Finish: Resin prints have incredibly smooth surfaces straight out of the printer, requiring little to no post-processing compared to FDM prints that often need sanding and smoothing.

What if you need to 3D Print with Carbon Fiber or materials that only come in filament form

If you have to use filaments, then a good FDM 3d printer is the only option. But a so-called high speed 3d printer isn’t actually going to print those materials fast.

Not because the printer is bad, but because of the way those materials are.

The head’s output rate matters, & not just the movement speed

So how should we 3D Print Carbon Fiber & Functional Filaments Fast?

Professional machines with High output heads can print Carbon fiber & functional filaments reliably & at fast build speeds without heavy XY movement.

A larger nozzle (e.g., 0.6mm or 0.8mm) deposits more material per layer, increasing interlayer adhesion and overall part strength.

Smaller nozzles (0.4mm or below) provide finer detail but often at the cost of structural integrity.

If strength is a priority, using a larger nozzle at moderate speeds is often better than printing thin, fast layers that result in weaker bonding.

But a majority of so called ‘high speed’ FDM 3d printers rely on small nozzles so that they can push out the material with their lower spec heads, & then move around extremely quickly to compensate for the fact that the nozzle is relatively small.

That style of extruding quickly with thin nozzles can look fast, but it is overall les efficient & makes weaker parts.

So while it looks really cool, in reality it is still not as fast as compared to entire layers being made on a resin printer.

Ultimately, if you need to print strong, industrial-grade materials, even the fastest FDM printer won’t solve the fundamental issues of warping and adhesion at high speeds unless you use an active heated chamber & slow the extrusion down – just like a good FDM should.

If you need to print such functional parts with filaments, buy one of our Professional FDM 3D Printers.

The Best 3D Printer for High Speed and High-Quality Parts

So, what’s the right choice? If you only print PLA or PETG for prototypes and casual projects, a high-speed FDM printer might make sense. But if you need strong, dimensionally accurate, and high-quality parts, to be produced at a fast rate, then a resin 3D printer is the superior option. With advancements in durable and engineering-grade resins, resin 3D printing is quickly becoming the go-to choice for both speed and performance.

If you’re serious about high-speed, high-performance 3D printing, it’s time to consider a resin printer for your workflow. Explore our range of professional resin 3D printers and discover the true potential of high speed and high quality 3d printing!

Are resin 3D Printers perfect at everything? Of course not, there are pros & cons to every technology.

For eg, if you want to 3d print with carbon fiber, you have to use a good FDM 3d printer.

And for that, a so called high speed one won’t really help, as you’ll need reliable layer adhesion & chamber management which only professional FDM 3d printers can give you.

If you are unsure, please contact us & our highly experienced engineers can guide you with honest advice.

For a deeper dive into how speed and quality are connected in 3D printing, read our in-depth guide here.