So what is IDEX technology & why is it such a big deal in Dual Extruder 3D Printers?

First lets explore what Dual Head 3D Printers actually refers to

Common 3D Printers with 2 heads, also called dual extruder heads, are essentially 2 filament output mechanisms attached side by side on a single ‘Head mount’.

For sake of convenience, these were still called ‘Dual Head’ & the terms dual head or dual extruder are used interchangably.

Whilst the system of connecting 2 extruders onto a single mounting side by side gave us great convenience for a low cost, it then started to cause certain usability issues.

For eg, 1 nozzle thats printing a part will have the other nozzle knock the part off.

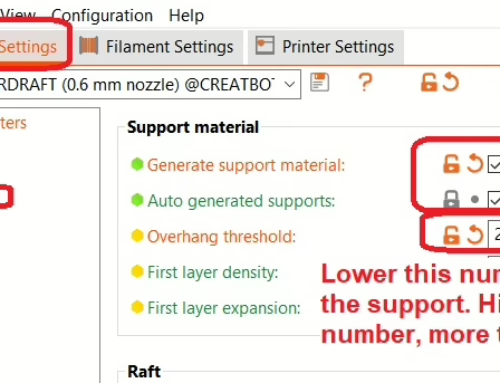

So some companies decided to make printers where the inactive nozzle lifts up & stops it hitting the part.

Great, but the problem was that the inactive nozzle was still hot & was dribbling & oozing material all over the part.

Now imagine if you were making a 2 coloured black & white model, its frustrating to have blobs of each colour on the wrong area.

Lets consider particularly advanced applications such as multi-material overmoulding or other advanced multi material 3d printing requirements.

Over Molding is a technique where 2 separate materials are to be 3d printed in a manner where 1 is enveloping the other to quite a great extent.

Sometimes, those materials may not want to stick to each other very well either, adding to your challenges.

Whether its 2 different materials, having to use separate support materials, or just using 2 different colours, the issues were the same.

A lot of people were able to successfully tune for these issues, but the fact is that it took more time, patience & careful tuning to use these kinds of multi-extruder single headed 3d printers in multi material applications.

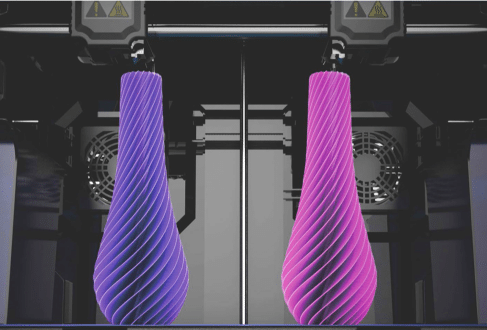

Now, what if 1 head could be parked completely out of the way while the other was 3d printing?

Firstly, you dont have to worry about the fact that each of the 2 nozzles are going to knock each others printed area out.

Secondly, you don’t have to worry about the hot plastic oozing out on your 3d printed area as its oozing on the side & cleaning up there.

On top of that, 2 separate heads means the weight of each individual head is reduced.

And reducing the weight to almost half, means greatly reduced inertia when the head is moving around.

It also greatly reduces the chances of your heads knocking the part out if you were to have not had ‘perfect alignment’ interfering with each other.

So you don’t need to be too worried of the individual alignment relationship of both ‘nozzles’ is perfect or not.

The system is fully automated. Yes you do need to align the heads, but each head only operating at 1 time allows better room for error.

You still need to get your temperatures, retractions, cleans etc correct, but at least the challenges are greatly reduced.

Hope this helps you appreciate 3D Printers with Dual Independant Extruders & why you would want to buy one..

Happy Advanced 3D Printing!