- Clean Delicately With Powerful Vortex - Equipped with a powerful bottom propeller, the washing station effectively cleans your models without causing damage to details.

- Dunk 10” Wide Building Plate Straight In - With extra-large build volume, you can clean almost any model, no matter how big! Best used with Sonic Mighty 8K and other 10” building plates.

- The Dual Fan System Makes Drying Easier Than Ever - Designed with a fan drying mode, you can pop printed models straight into the curing station to dry and cure them in one go.

- No More Sticky and Unevenly Cured Models - With 405nm UV lights radiating from the back and under the models, the curing station ensures extra effective curing.

- Time-Saving - Coming as a pair, the 8L washing station and the curing station with the dry & cure function are literal time savers.

-

Take away the mess & hassle of cleaning resin 3d prints by hand. The Phrozen Wash & Cure Kit will make your cleaning and curing process faster and easier. Thanks to its large washer and mathcing curing station, it can dry and cure your models all in one go.

-

This is the genuine tapered full metal angled build platform for Phrozen Sonic Mini & Mini 4K 3D printers. It is a fully angled bed to allow the resin to flow down smoothly. Using this build platform will minimize resin accumulation on the top of the plate, allowing it to more readily drip back into the vat during printing. This makes clean-up and print removal faster, easier, and less messy overall so that you can spend more time printing. If you print a lot, or print very fast, or print larger parts, this all-metal build plate is the perfect choice.

-

This is the genuine full metal angled build platform for Phrozen Sonic Mini & Mini 4K 3D printers. It is a thick solid bed to allow maximum print speeds without distortion. If you print a lot, particularly if you print larger layers at once, then this full metal build plate is the best choice.

-

This is the full hot end which gives you new extrusion components under the motor. It includes the heat brake, throat tube, hot block, & a 0.4mm nozzle. It comes fitted with a new cartridge heater & a thermocouple temp sensor as well.

-

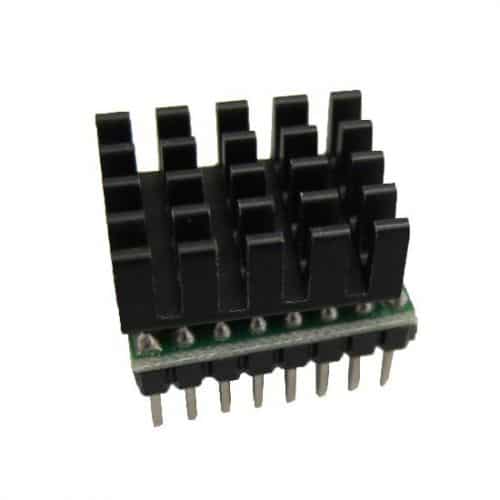

These are the drivers used to drive the stepper motors on Creatbot 3d printers. They are used for the X Y Z axi motors as well as for the Extruder motors. Different drivers have been used for the X Y axi as well as for the Z & E1 / E2. Please choose the correct model number. If the model you have is not listed, please contact us & we will set it up for you.

-

So we have fast resin 3d printers now, but have you thought about post processing faster? Take away the mess & hassle of cleaning resin 3d prints by hand. And dont wait nearly 50 mins to be able to use your 3d prints with conventional wash & cure devices. With our Ultrasonic 40KHz industrial style washer & a Heated UV Curer, you will speed up your post processing time down to just 15 mins. Thats just 15 mins from when your print is out to when a usable part is in your hand. Standard curers do not heat the chamber. Heating not only speeds up the cure, but more importantly, it significantly improves the internal structural integrity of your part. Normal washer devices tend to rely only on the standard dissolution rate of resin into the cleaner. Whereas ultrasonic cleaners actively separate the resin stuck to the part with a 40KHz wave, thus speeding up the cleaning process dramatically. Wash for just 5 mins with resin cleaning liquid in the ultrasonic & then cure for 10 mins in the heated curer - you have your self a factory quality usable 3d printed part!

-

Why use Ultrasonic cleaners when Wash & Cure units seem to be so popular? Ultrasonic vibrations loosen out debris from any surface surface efficiently & quickly using harmless forces. The frequency of motion they form safely dislodges uncured resin particles at a microscopic level that other devices cant create. Ultrasonic cleaners can clean most resin parts in 3 mins. Most entry level washers can't beat that. The fact that there is no heavy movement, allows debris to settle rather than float around. This makes it far easier to get the parts clean with less fluid use. Resin cleaning liquids like Monocure Resin away & Phrozen now make it a cheaper & safer option than to use IPA or other explosive alcohol based cleaners. When cleaning castable resins or industrial resins in particular, ultrasonic cleaners will give you the edge.

-

This motor is used in the Creatbot F430 3d printer. It is the X axi motor that connects on the linear rail to move the head left to right. This is the motor only, not the fan/heatsink. Please remember to put the heatsink & fan from your old motor onto the new motor.

-

Genuine Creatbot door handles. These are the slim thin silver coloured aluminum door handles on newer Creatbot 3d printers with hinged doors. They are the smaller size (approx 80mm long), which are used for DX, DE, F160. They are also used on the rear chamber doors of the F430. These are attached to the Acrylic doors on the D series, & corresponding door frames on F series machines.

-

This is a temperature sensor for the newer FlashForge Creator Pro 2 & Creator 3 Pro 3d printers. It is a threaded type that fits into the hot end block. This is not for older flashforge Creator series printers.

-

Latest ACF Film for 15" LCD Resin 3D Printers The new Phrozen ACF film is designed with a non-stick and smoother film surface for more efficient 3D printing. Compared to FEP and PFA (nFEP) film, the ACF film features a better release, reducing the printing time and increasing the success rate. ACF is the strongest, & has the highest tear tolerance. It also has the lowerst peel force so suction forces are minised & you have the best print possible. NFEP film (also called PFA Film) is better than the old FEP film to reduce suction forces. ACF takes this to a whole new level. ACF film is the best choice for printign high performance enginering resins such as the Onyx series, Henkel & BASF industrial series, etc. It is a sginifcatly bettter non-stick surface so it reduces peel forces greatly. So parts are less likely to stick to film or pop off from the build plate. This FEP Film is suitable for the biggest of printers like Phrozen Mega 8K 15", Transform 13", etc Can also work with smaller DLP LCD 3D Printers, simply cut the sheet in half & you have multiple ACFs! This will work with Metal or Plastic vats. Very easy to use. Simply open the screws on your vat, remove the old FEP sheet, & put this sheet in place. Please see the video below to see how easily you can change the FEP on your Phrozen Sonic Mini Resin 3D Printers. You should change your FEP film when its cloudy, has excessive scratches, or you find the prints stick to it too easily rather than the bed. Depending on several factors, this is usually around 200 hrs of use. FEP is like a car tyre, you can have the best mechanics but without a good tyre, you're asking for trouble. We keep our prices on consumables cheap to help kiwis get the best results with 3d printers without prolonging the need to replace important components. Also check out the PlateBond Adhesion Promotor to help your base layers stick better to the bed of your resin 3d printer when using challenging materials at faster speeds.

-

Why use Ultrasonic cleaners when Wash & Cure units seem to be so easy to use? Short answer, high speed & less manual work. Ultrasonic vibrations loosen out debris from any surface surface efficiently & quickly using harmless forces. The frequency of motion they form safely dislodges uncured resin particles at a microscopic level that other devices cant create. Ultrasonic cleaners can clean most resin parts in 3 mins. Most entry level washers can't beat that. The fact that there is no heavy movement, allows debris to settle rather than float around. This makes it far easier to get the parts clean with less fluid use. When cleaning castable resins or industrial resins in particular, ultrasonic cleaners will give you the edge.