Lets talk about the best nozzle available

Martensitic Steel nozzles are the Best Quality of Hardened Steel nozzles for 1.75mm filament 3d printers to print high temperature & composite reinforced materials.

Perfect for 3d printing Carbon Fiber, Glass Fiber, Kevlar, etc

There are many different sizes of nozzle diameters, which refers to the small hole from which the molten filament is pushed out.

Nozzle size usually refers to this diameter, however, the term size also applies to the actual size & thread of the nozzle itself.

Our printers use the most common type called a Mk8 size, based on the Mk8 threads.

Examples include our Creatbot F430, F160, PEEK300 & D600 Pro 3d printers.

Martensitic Steel is the best material presently available to make nozzles out of.

They are the most durable nozzles compared to brass or stainless steel.

There are many other hardened materials available, so why use martensitic steel?

Hardened martensitic steel allows much cleaner retractions than brass nozzles, which interestingly also improves the overall print quality.

Steel provides very good heat transfer. It expands slightly in the hot end, thus minimizing leaks & dribbles.

These nozzles can be used with Carbon Fiber filaments & all high temperature materials include PEEK.

0.4mm is on the smaller side for carbon to flow through well.

Milled Carbon Fiber Nylon when printing small parts should be ok, but for larger longer prints, we recommend using 0.6mm nozzles for Carbon Fiber composite materials.

These are well suited particularly for advanced materials that print at ultra high temps like PEEK, PEI Ultem, PPSU etc.

Our nozzles are individually machined for optimum precision & longer life (not just die casted & pressed like inferior nozzles).

They can be used with all Mk8 compatible 3d printer heads.

So what sets our nozzles apart from the competition, particularly the cheaper nozzles that look almost the same?

Our martensitic nozzles are individually turned as part of the main production process, not just die casted like budget nozzles.

They are extremely precise, well machines parts that will out last other products.

And that is the reason why they cost much more than cheaper nozzles, but you will appreciate the value they bring to your 3d printing.

Whilst any nozzle can block or choke, at least with these nozzles you get precision & longer wear resistance.

What is the perfect nozzle size to use?

The standard nozzle diameter that comes with the machine is 0.4mm

Use a 0.4 if you want precision, but as you go larger, you will be able to build the model much faster.

A 0.8 mm nozzle on average can finish the build 6 times faster than a 0.4mm!

But also remember big nozzles mean less detail in the model, so avoid them for minute things or parts that have lots of support interface where the support is being printed with the same material as the part.

0.6mm nozzles offer almost double the throughput with minimal noticeable difference in output quality.

This is why 0.6 have now become our most common nozzle size, because it aids printing Carbon Fiber really well.

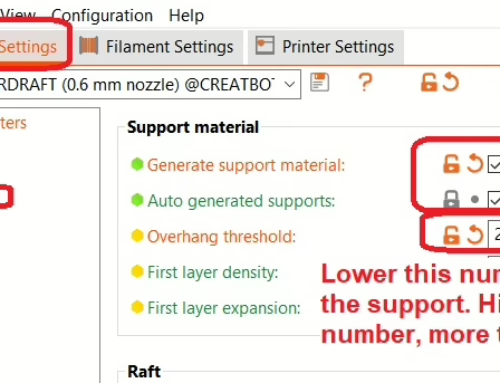

You need to adjust settings in your software to ensure you print with the larger sizes properly.

Please remember that nozzles can choke due to contaminants.

A brand new nozzle may print for 5 mins & choke if you are loading anything contaminated into it.

This is not a fault in the nozzle, but rather contaminants in the filament or dirt or known additives (like carbon fibre) that are choking the nozzle.

Nozzle cleans are very possible in such cases, & you may still be able to continue using the nozzle for its expected life.

The cleaning filament can help do this with more ease.

Please read here on how to clean your 3d printer head with cleaning filament.