Firstly, what is Wood Filament ?

All Wood filaments are actually made by adding Wood Fibre into a base plastic, most commonly PLA.

Thus, most wood Filaments are called Wood PLA.

Most cheap Wood filaments are PLA with only around 5% of Wood fibres in them.

These wood fibres are made in the same way as those used in MDF wood sheets.

When you ‘Print’ Wood, what you are actually 3d printing is the plastic that is holding all that Wood together.

How to best 3d print with Wood

Remember that the base polymer is what guides the initial settings, like extruder temperature & build plate temperature.

In this case, its PLA, so that makes life very easy.

However, people often find that when they 3d print large items out of wood, the machine blocks after a couple of hours, & they have to make their part in many pieces.

Let’s understand why, & how to minimize this.

There is one important element in 3d printing wood reliably that no properly explains…and thats nozzle size.

All plastic materials that additives in them, such as wood, metal powder, or carbon fibre are best printed from larger nozzles.

The larger diameter hole in the nozzle helps push more of that additive out without easily blocking the small hole of a nozzle.

For eg, most 3d printers are preset with 0.4mm nozzles. With that 0.4mm, you are asking wood powder to squeeze out of a small hole.

Ideally, you want to use a bigger hole. 0.6mm hole might sound like just a tiny bit bigger than 0.4, however, a 0.6mm nozzle allows you to push double the amount of ‘volume’ of plastic & thus makes 3d printing wood a piece of cake!

Now, the cheapest 3d printer makers don’t supply nozzles of a larger size, because cheap machines struggle with larger nozzles.

You can still buy aftermarket nozzles in many machines, but what if you dont want to hassle with that??

Then the first thing you want to be mindful of is printing with as Fat a layer height as possible.

With a 0.4mm nozzle, you can print a 0.3mm layer height reliably, so use that.

But when you are printing fat layers, you MUST slow down the print speed.

So, lets discuss the 2 common scenarios on 3d printing wood:

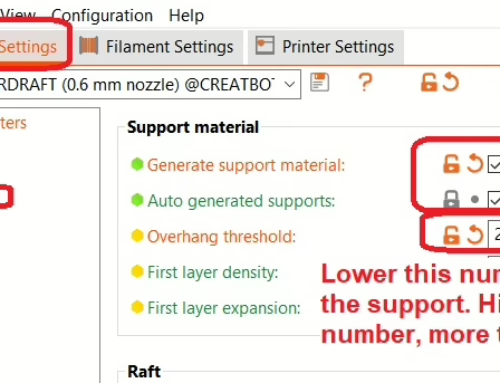

With 0.6mm nozzles printing 0.3mm layer height, use 230C Head Temperature with at least 60C bed temperature.

The fatter nozzle will allow thinner layers, because it is wider, so, the layer height can be thinner if you want to.

Remember that the printing temperature relies on throughput. So, with fatter nozzles we are printing with more heat than we wuold for say a 0.4mm nozzle.

Do not go down below 0.2mm else problems may arise.

Print Speed 30-40mms is fine now because the nozzles & head should be able to handle it.

Turn off retraction, but add some with experimentation.

With 0.4mm nozzle, print 0.3mm layers at 220C

Print speed no more than 20mm here because you are asking a small nozzle on a small head to work hard.

Printing lower than 0.3mm layers is best to avoid as the head may be blocked by the fibres.

But for small parts, it will be ok if you printed at 0.2mm. Any less, & you have a high chance of blocking.

Do not try to print fatter extrusion lines than what your nozzle diameter is.

So, with a 0.4mm nozzle, do not print 0.5mm lines & expect that will lead good results. Infact it will be worse.

Never print items with additives in that way.

The interlayer adhesion of a 3d printed part is crucial, & in materials that have additives, that adhesion is often reduced.

Wood powder will not stick between layers, it is only the PLA that is bonding.

So, to get a god bond between layers, do not over cool your print.

Sometimes, you may find that when wood is printed, it looks fantastic but quickly breaks, or delaminates.

Delamination means the layers peel off if you put a bit of force on them.

So to avoid this happening, keep your fan speeds around 50% rather than the usual 100% you might be using when you print Pure PLA.

This allows you to compensate for the otherwise reduced amount of polymer being pushed out when printing, so it does not overcool that plastic & allows it to bond better with the previous layer.

Can you work with Wood 3d prints just like real wood?

There are 2 elements to working with wood. Manufacturing, & post processing.

With 3d printing, the manufacturing part has to be done. Do not attempt to use a carving chisel to chip wood 3d prints. They will crack.

You can stick wood 3d prints with PVA based glue. It will not be super strong, but it will work!

Best to use Epoxy if strength is needed.

However, in terms of post processing, well thats where wood 3d prints are awesome.

You can sand, lacquer, even stain wood 3d prints & despite the plastic, you will actually see some of that stain being absorbed.

You can also spray a PU coat on the print.

So when it comes to making good looking things, wood PLA filament is awesome.

Happy 3d Printing!