- Density 1.27 g/cm³

- Tensile Strength 90 MPa

- Elongation at maximum force 5%

- Modulus of elasticity 3 GPa

- Flexural strength 150 MPa

- Flexural elongation at max. force 6%

- Flexural modulus 2,5 GPa

-

Polyether Ketone Ketone (PEKK) is a semi-crystaline thermoplastic in the Polyaryletherketone family. It has higher heat resistance than PEEK, offers exceptional chemical resistance, & can withstand high mechanical stress. It is inherently flame retardant and has unique tribological properties unlike any other ultra performance polymer currently available for 3d printers. PEKK has a higher Tg than PEEK. PEKK is also easier to print compared to PEEK. PEKK has now overtaken PEEK as the best FDM 3d printing material. LUVOCOM® 3F PEKK 50082 Material Properties

-

So we have fast resin 3d printers now, but have you thought about post processing faster? Take away the mess & hassle of cleaning resin 3d prints by hand. And dont wait nearly 50 mins to be able to use your 3d prints with conventional wash & cure devices. With our Ultrasonic 40KHz industrial style washer & a Heated UV Curer, you will speed up your post processing time down to just 15 mins. Thats just 15 mins from when your print is out to when a usable part is in your hand. Standard curers do not heat the chamber. Heating not only speeds up the cure, but more importantly, it significantly improves the internal structural integrity of your part. Normal washer devices tend to rely only on the standard dissolution rate of resin into the cleaner. Whereas ultrasonic cleaners actively separate the resin stuck to the part with a 40KHz wave, thus speeding up the cleaning process dramatically. Wash for just 5 mins with resin cleaning liquid in the ultrasonic & then cure for 10 mins in the heated curer - you have your self a factory quality usable 3d printed part!

-

Why use Ultrasonic cleaners when Wash & Cure units seem to be so popular? Ultrasonic vibrations loosen out debris from any surface surface efficiently & quickly using harmless forces. The frequency of motion they form safely dislodges uncured resin particles at a microscopic level that other devices cant create. Ultrasonic cleaners can clean most resin parts in 3 mins. Most entry level washers can't beat that. The fact that there is no heavy movement, allows debris to settle rather than float around. This makes it far easier to get the parts clean with less fluid use. Resin cleaning liquids like Monocure Resin away & Phrozen now make it a cheaper & safer option than to use IPA or other explosive alcohol based cleaners. When cleaning castable resins or industrial resins in particular, ultrasonic cleaners will give you the edge.

-

Genuine Creatbot door handles. These are the slim thin silver coloured aluminum door handles on newer Creatbot 3d printers with hinged doors. They are the smaller size (approx 80mm long), which are used for DX, DE, F160. They are also used on the rear chamber doors of the F430. These are attached to the Acrylic doors on the D series, & corresponding door frames on F series machines.

-

Monocure Gingiva is presently our best flexible resin for Lcd resin 3d printers. It is stronger than the general monocure Flex resin, & more flexible than the Esun Elastic resin. This gingiva flex resin has excellent mechanical properties that work well for flexible engineering parts as well as emulating 3d printed gums in digital dentistry,. With a shore hardness of 62A, you can make rubber like parts using your LCD Resin 3d printer. GINGIVA Dental Flexible Resin helps improve implant workflows and produces natural-looking, flexible gum-like parts for dental implant models. The elastic material is highly tear-resistant, flexible, and easy to adjust via grinding if needed.

-

Why use Ultrasonic cleaners when Wash & Cure units seem to be so easy to use? Short answer, high speed & less manual work. Ultrasonic vibrations loosen out debris from any surface surface efficiently & quickly using harmless forces. The frequency of motion they form safely dislodges uncured resin particles at a microscopic level that other devices cant create. Ultrasonic cleaners can clean most resin parts in 3 mins. Most entry level washers can't beat that. The fact that there is no heavy movement, allows debris to settle rather than float around. This makes it far easier to get the parts clean with less fluid use. When cleaning castable resins or industrial resins in particular, ultrasonic cleaners will give you the edge.

-

Monocure 3D GUIDE™ bio-compatible 3D resin is skin contact & intra oral certified by the TGA in Australia. It has been engineered to fabricate medical & dental appliances like surgical guides. It has a high heat resistance and is suitable for sterilisation using standard autoclave protocols. Once post-cured, this material has high tensile strength and is transparent, odourless and tasteless. Monocure 3D’s Surgical GUIDE™ is transparent and is certified as a biocompatible Class I material by the Australian Register of Therapeutic Goods (ARTG) No. 398012 It was developed for high-precision implant-guided surgeries. The high-resolution, rapid layer speed and exceptional mechanical properties provide the ultimate implant assistance.

-

Luvocom® 3F PEKK 50082 3D Filament

PEKK Filament is easier to print than regular PEEK filament with better layer adhesion while offering similar strength and resistance properties, & better dimensional stability than PEEK. PEKK also has a higher Tg Glass Transition Temperature than PEEK. This unique modified neat PEKK is a low warp formluation that provides dimensional stability in delivering semi-crystalline parts with no warp. Polyether Ketone Ketone (PEKK) is a semi-crystaline thermoplastic in the Polyaryletherketone family. With high heat resistance, chemical resistance , has the ability to withstand high mechanical loads, is inherent flame retardant and has unique tribological properties. PEKK Filament has a tuneable crystallization rate which allows FFF or FDM users to take advantage of both the extreme performance of PAEKs and easier processing of amorphous materials. Made in Netherlands by 3d4makers using Lehvoss genuine luvocom resin. We always recommend an active heated chamber for 3d printing all advnaced materials including PEKK. But this particular grade gives you a good chance of printing simpler smaller parts without a heated chamber. 200g roll in a natural brown beige colour. Want to 3d print this material routinely? Consider our Creatbot PEEK-300 industrial material 3d printer. -

3D4Makers PCL 100 3D Printing Filament 1.75mm 750g

Facilan™ PCL 100 is a highly functional filament made from polycaprolactone, perfect for advanced medical applications. It can be reshaped in water at 55 °C after 3D printing due to its low melting point. This material is widely used in the development of artificial tracheas, smart materials, tissue engineering scaffolds, bioabsorbable implants, and more. Renowned universities and research centers worldwide trust Facilan™ PCL 100 for cutting-edge bioprinting and personalized medical research. With its flexibility and toughness, this filament has a glass transition temperature of -60 °C and a print temperature of around 120 °C. Its semi-crystalline aliphatic biodegradable polyester composition gives it a distinctive white appearance. Complying with European regulations, the filament produced by 3D4Makers is safe for use with food contact. Additionally, it offers excellent adhesion between layers, enhancing impact resistance, strength, durability, and print quality. -

3D4Makers Ortho 3D Printing Filament 1.75mm 750g

Facilan™ Ortho Filament is a 3D printing material specifically designed for orthopedic applications. It is a durable and flexible filament that offers exceptional mechanical properties, making it ideal for creating customized splints, braces, and other orthopedic devices. One of its unique features is its excellent adhesion to textiles, allowing easy combination and bonding with textile inserts or other shoe components. Additionally, the low melting point of Facilan™ Ortho enables it to be easily reshaped with warm water after 3D printing. Made from a unique blend of biocompatible polymers, this filament ensures patient comfort and excellent skin contact. Facilan™ Ortho Filament provides healthcare professionals with the ability to tailor orthopedic devices to individual patient needs, facilitating faster healing and recovery. With its high printability and compatibility with most desktop 3D printers, this innovative material is revolutionizing the orthopedic industry. Facilan™ Ortho is a versatile and high-quality polyester, known for its clean white appearance. It exhibits exceptional mechanical properties and has a density of about 1.2kg/cm3. With a melting point around 60°C, it is a safe and easy-to-print thermoplastic. The flexibility and toughness of Facilan™ Ortho, attributed to its glass transition temperature of -60°C, make it highly durable. Moreover, it is a biodegradable plastic, meeting compostability standards according to EN13432. -

Big Parts, High Accuracy, & Reliability - In ALL Filament Materials currently available. The Creatbot D600 Pro is based on the successful D600 commercial grade FDM 3D printer. It features Servo Controlled motors & closed loop feedback electronics, giving it the most precise head calibration of any similar sized large scale 3D Printer on the market. It has become common to see low cost large size 3d printers on the market. So why would you buy this one? Just doubling the size of every single part & giving you a large bed, doesn't lead to a successful print. With cheaper printers you will see them advertise a size like 500x500mm, but when you actually try to print a part that size, your builds will consistently fail. Multi-day prints will be composed of layer shifts in the XY direction, even a 0.1mm XY shift will land your part in the rubbish bin. This is why real commercial grade 3d printers are designed to be able to produce what the spec sheet actually has on it. And that is the reliability you need, so that you dont come back to a 3 day print only to throw it in the bin. Large 600mm x 600mm x 600mm actively convection heated build volume makes it possible to print large parts one piece with ease. And the servo control system doesn't cause stepper drivers to overheat, which is all too common in kit style large 3d printers. Suited to producing large yet highly accurate 3d models, the D600 has every professional grade feature you would expect. Contact us today to see how our leading edge Creatbot D600 could give you the edge in product development & manufacturing. Please see full specification details below. Free training is offered with our Creatbot D600. We will spend several hours with you to discuss any product specific requirements & help you get the best possible outcomes from these 3d printers. We will also help you implement the 3d printer into your workflow, so you can rely on a team right here in Auckland. We also offer Free Phone based support, not just email. All spare parts are stocked right here in Auckland & sent same day in most cases with overnight courier. So should you need a spare part, your 3d printer isn't sitting there costing you money. Its surprising how many 3d printer companies advertise machines but don't stock parts for when you need them the most. We are New Zealand's EXCLUSIVE Creatbot Partner. We are also authorised Creatbot suppliers for Australia. We are the only company in the region to offer FREE TRAINING with these 3D Printers so that you fully supported after buying the 3D Printer & not left alone to figure things out. There is no extra charge for this support service. This is the commitment we have put into the New Zealand & Australian 3D Printing Market - We want you to succeed with 3D Printing, & in your success is our success. We aim to have the BEST PRICE & BEST SERVICE for Everything 3D Printing in NZ / AU.

-

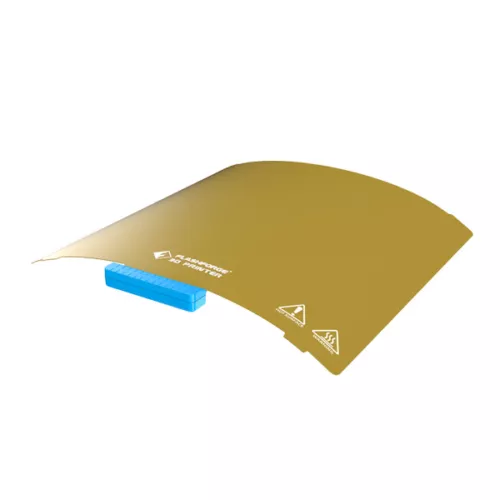

This is the latest flexible build plate that fits on the new magnetic beds of FlashForge Creator 4 3D Printers. It now has a PEI reinforced build surface that provides excellent adhesion to most common materials including flexible TPU materials. It also gives a very good bottom surface finish. It is superior to the older Black plates that FlashForge used to supply. We highly recommend PEI sheets as the best surface to print on. For Nylon based materials, we still recommend you put a thin layer of the glue stick on it.